A Pioneer Technology of Crystal Elements

Dear Sirs,

This webpage demonstrates the pioneer technology of quartz sensors and resonators

I decided to publish my technological achievements first in 2000 at International Simposium, but because of some reasons not depending on me was not able to do so. That is why I present my abstracts, sent to the Programme Committee, without any changes after its edition in 2000. You can find the text below.

Newertheless intensive work to improve the technology continues till now and I would like to inform you about my latest achievements.

Realizing that a question might arise why I do so, I prefer to answer it immediately. In the development of the technology we are on the stage when it has examined and we have all major answers concerning the capabilities of the technology. Now we are searching for a strategic partner who could launch and to put into production (practice)the technology.

You can find below only facts, proved by the photos of the experimental samples.

General possibilities (capabilities or advantages) of the technology are the following:

- Extremely high speed of quartz dissolutions reaching 20 and more micron per minute

- Very high polishing effect

- Isotropic dissolutions of quartz

- A possibility of chemical etch using a cheap chemical mask put on DESTROYED SURFACE layer though it seems incredible it is proved fact

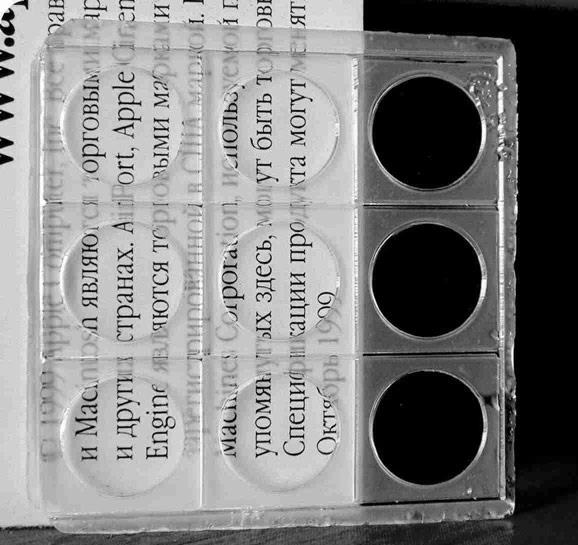

- Possibility of Lenses production in photolithographic process. The lens always get polished, not taking into account the condition of blank before the process

- Ability to create sophisticated quartz devices on quartz wafer such as for instance as pressure,force accelerometer sensor and etc

- Possibility to use this technology in construction of sophisticated mechanisms, with ( ?) the usage of any other silicates as glass, langasite

- Technology can be easely used with the others technologies of surface treatment for example inverted mesa technology

- Technology was used on different cuts of quartz and the best results were achieved with SC cut

- Technology does not use poisoning materials and has a very limited even maybe no negative effect on environment.

- Technology does not use high pressure and temperatures which puts it into the row of (safe usage) technologies.

- Possibility, using the acumulated knowledge, to examine its usage in traditional fields such as cutting or grinding, and I assume that the results achived using this technology might be similar to those using the diamomd tools, though without lattice damage

- As development of this technology some materials might be created as nonorganic printing boards for OSXO or sensors or it all together

By now it is very difficult to distinguish all the fields where technology might be implemented, and the ways it is used might be most unexpected, such as optical devices or glass art

This technology was developed by several scientists and the first results were so IMPRESSIVE THAT THE SCIENTISTS CONTINUED WORKING on the technology at their own expenses and enthusiasm.

Unfortunately this fact was limiting future development of technology and the samples were not finished, though mathematical models of process and nesessary equipment were developed

On the webpage you can find almost all documentation prepared for while working with technology, even unsuccesful experiments.

We hope that you will have a possibility for a deep study of this site and possible future cooperation.

Sincerely yours,

Mironenko Igor

A Pioneer Technology of Crystal Elements. Abstracts

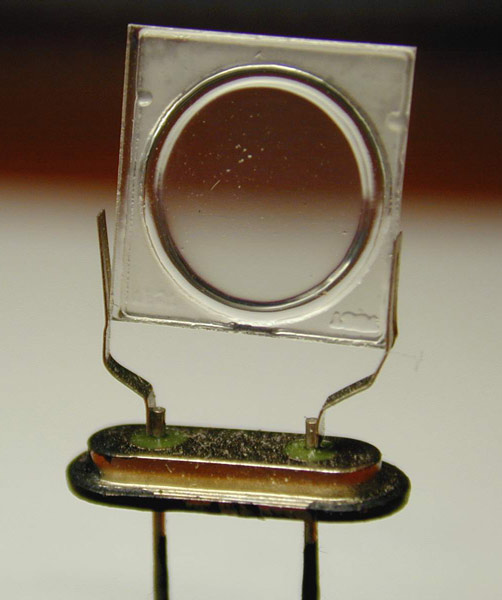

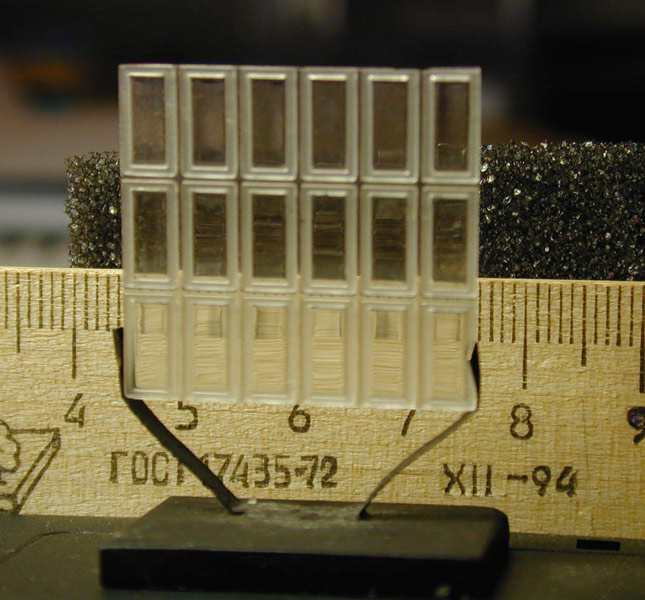

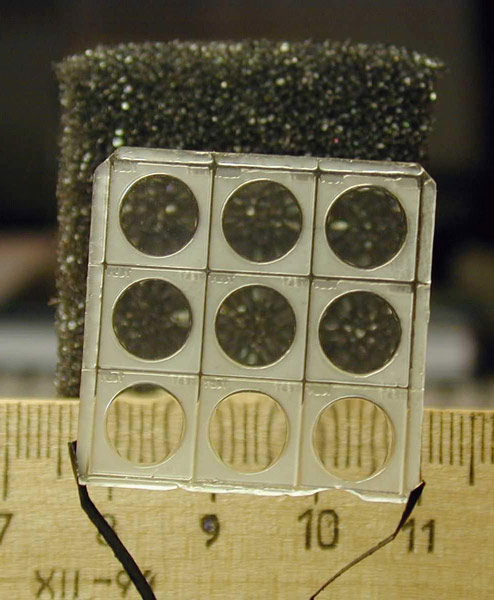

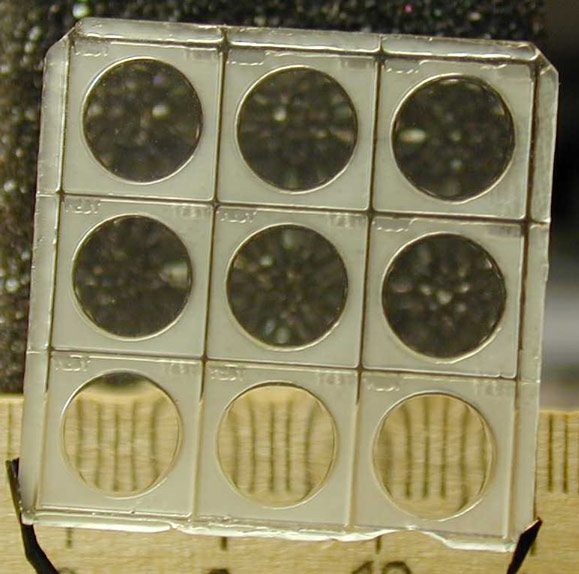

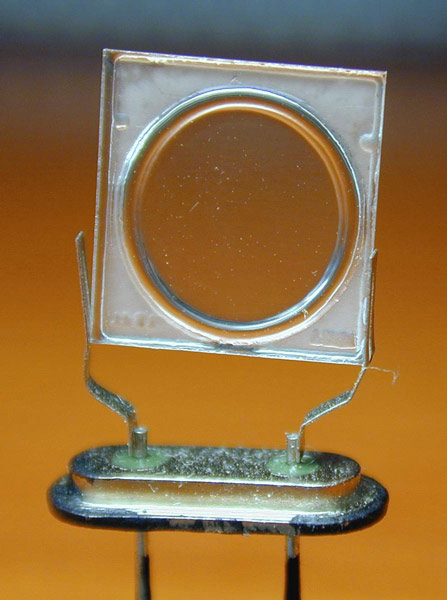

A new batch technology for manufacturing the structures of bi-convex lenses on a wafer made of AT and SC quartz cuts is developed. This technology uses the "volume" lithography when the lens-shaped polished elements are manufactured by the presented method of quartz chemical dissolution with a high process speed reaching 20 microns per min. The lens shape of the elements is achieved by controlling the diffusion properties of the reagent dissolving quartz. A method that does not require the removal of the quartz layer destroyed while grinding is used for the defending lithographic mask deposition. The lithographic mask is made by purely chemical method and does not require costly surface cleaning and the clean room such as for vacuum metallization in the inverted mesa or tuning fork technologies.

The high quartz dissolution speed also allows manufacturing complex contour elements with the thickness of up to 0.3-0.5 mm during appropriate time by through etching.

When quartz is processed by this technology, etching channels never appear in quartz of any quality, and the surface is optically transparent or with small scattering with Ra≤0.05°µ.

This quartz chemical processing technology provides a very high isotropy of quartz dissolution, which makes it possible to manufacture lenses and other axially symmetric shapes.

For the first time, this technology makes it possible to manufacture several lenses at one wafer that is cut after the lenses have been manufactured.

Samples of AT 10/1 and SC 13/3 resonators are manufactured by this technology, and the batch process of lens manufacturing on a single wafer has been prototyped. At that, there is found an interesting feature allowing the control of the position of the turnover point during the manufacturing process. With this, there is no need to obtain accurately the cut angle of the wafer. The accuracy of 1'-2' is enough. It is only necessary to know accurately (15'') the actual angle. The angle is corrected to the required turnover point by predictable mask shifting before bi-sided exposure of photoresist in the lithographic process.

All these feature of the presented technology allow us to say that this is a pioneer technology that shows new horizons in the quartz industry.

|

|

|

|

|

|

|

|

|

|

|